solar fruit and vegetable drying machine

Drying Case Show

Product Description

3HP domestic heat pump dryer

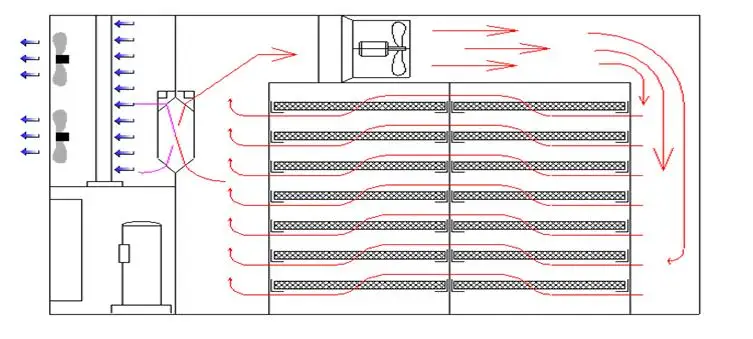

At present, most of the drying device adopts three-phase electric power for drying operations, but the majority of farmer customer groups there are no provide of three-phase electric power, most of them use burning coal, firewood or by natural to dry products. In view of the existing situation of the market, we design a small energy saving dryer to solve this problem. The main power of the product is the 220V individual civilian power, rated power 3.7KW.The perfect hot air circulation structure and the reasonable uniform wind distribution design have ensured the quality of the drying product.The heat recovery technology has achieved the highest energy saving 80% comparing with the electric heating dryer. In the rural household market, in addition to drying products, but also can use as an 3hp air-conditioning unit for free as multifunctional use for one machine.

Parameter&Feature

|

Technical Parameters

|

|

|

|

Integrated heat pump dry system

|

|

Power

|

|

220V/2N/50HZ

|

|

Compressor

|

type

|

3HP

|

|

other

|

Fully enclosed scroll compressor

|

|

Evaporator

|

|

aluminium

|

|

condensator

|

|

aluminium

|

|

Rated input power

|

|

3.5KW

|

|

Rated input current

|

A

|

13A

|

|

Maximum temperature /rated temperature

|

℃

|

85/80

|

|

Refrigerant Volume

|

KG

|

4

|

|

Ambient temperature

|

℃

|

>0

|

|

size (L×W×H)

|

mm

|

2800*1100*2200

|

|

insulation thickness

|

mm

|

50

|

|

tray quantity

|

pcs

|

40

|

|

tray size

|

mm

|

640*460*60

|

|

tray material

|

|

aluminium

|

|

equipment weight

|

KG

|

600

|

|

Noise in 1 meter

|

dB(A)

|

55

|

|

Exhaust Maximum temperature

|

℃

|

115

|

|

Exhaust pressure

|

Mpa

|

≤2.35

|

|

Return air pressure

|

Mpa

|

≥0.03

|

Domestic multifunctional heat pump dryer system characteristic advantage:

1,Super high temperature:Out of the wind temperature to 85 degrees, after 10 years of time to use the market test, the first investment in the use of the industry.

2,Uniform material: after the condensation of the high temperature wind through the flow of material to the material, so that the material is evenly heated dehydration.

3,Wide range of application: agricultural products, industrial products, seafood and other more than 20 industries.

4,Super high energy saving: the use of heat recovery technology, based on the automatic humidity of the baking room humidity, energy efficiency in more than 70%.

5,Low carbon emission reduction: no pollution, no waste water, waste gas and waste residue discharged during drying process.

6,General power: 220V/50HZ, non industrial use of electricity, every family can have.

7,Easy to use: self casters, mobile and convenient, machine factory.

8,Design concept: the unit baking room one, no need to install the site, then use the power.

9,Automation control: the use of integrated control system, man-machine interface, automatic control without personnel on duty.

10,Overall size: 2800*1100*2300, material tray 40, material plate size: 640*460*25.

11,Equipment energy consumption: unit full load power 3.7KW, equipped with 6 square wire, theoretical drying weight 400 kg.

12,The gospel of entrepreneurs: you can start a business, you can help people to process

Details & Schematic

Company Information

FAQ & Certificate

Q1:Are you factory ?

A1:Yes,welcome to visit our factory at any time.

Q2:All product have a warranty ?

A2:Yes,all kinds of our products have 3 years warranty at least.

Q3:What is the payment terms?

A3:T/T and L/C etc.

Q4:Can we design packing ?

A4:Yes.

Q5:Can we customize product?

A5:Yes,ODM is welcome

Packaging & Shipping

Contact Information